Investments in technology and trainees

08.11.2018

Koechow. It is eight o'clock in the morning when the special forklift lifts the new CNC lathe from the truck. He carefully transports the valuable new machine to its future workplace. The events are monitored and documented by the two managing directors Anja Wendt and Uwe Eilers.

Investment from EU funds

The lathe is one of four new machines at FMG Förderelemente Mecklenburg GmbH and the second to be delivered. “The automatic reaming machine is already here. Now we are still waiting for the automatic welding machine with the extractor and power source and a so-called washing machine, which are custom-made, ”says Anja Wendt. The total costs for the acquisitions amount to 287€. This is part of an EU-supported scheme funded by the European Fund for Regional Development and the bank OSPA. "An acquisition supported by the state of Mecklenburg Vorpommern using grants from the Joint Task GRW as well as from the European Regional Development Fund" explains Anja Wendt.

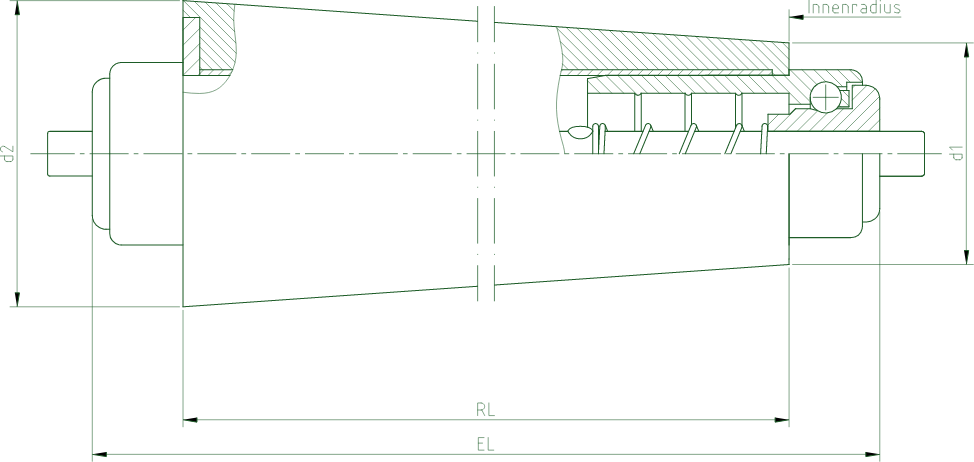

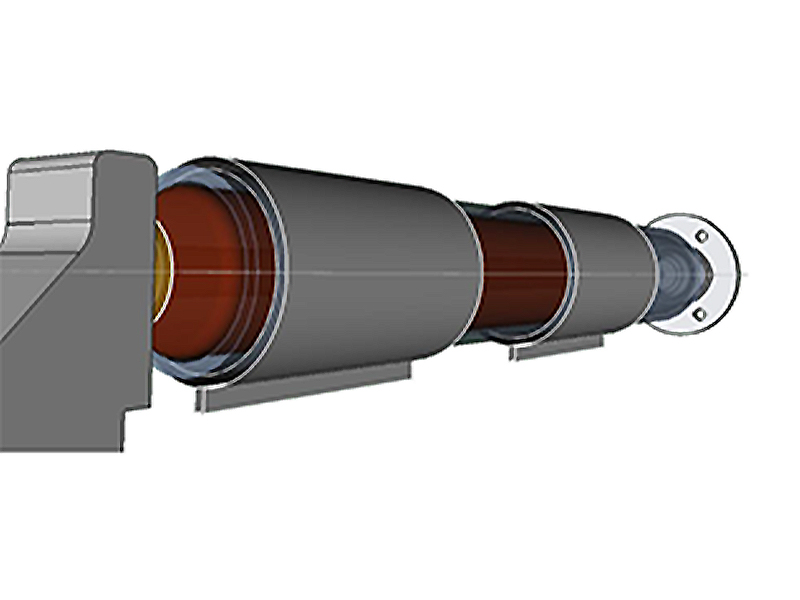

The machines are now supposed to increase the output volume and eliminate production shortages. “The computer-controlled lathe alone will be twice as fast as its predecessor. The data can now be saved and can be called up at any time, ”says Uwe Eilers.

Family company est. 1991

Anja Wendt and Uwe Eilers will be supported by senior partner Bernd Lehmann until the end of this year, when he will retire. the FMG Förderelemente Mecklenburg GmbH is a German, medium-sized company. Founded on November 29th November 1991 by Thomas Schuster - father of Anja Wendt - together with his former engineering colleague from the Rostock Neptun shipyard, Bernd Lehmann, and five men from the LPG "German-Soviet Friendship Society", on Waldweg in Körchow. "We have successfully specialized in the manufacture and distrubution of conveyor technology components and done so with great success" explains Anja Wendt.

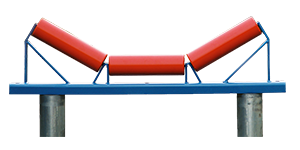

The company manufactures and sells transport rollers for general cargo and bulk materil as well as support rollers mainly made of steel and plastic. There are currently 45 employees working in production, management and sales. For more than a year now, apprentices have also been trained: one in office management and a specialist for metal technology. Apprentices will again be hired for the 2019/2020 training year.

FMG delivers 80% of its output across Germany an Europe - to Austria, the Czech Republic, Slovakia, Belgium, Poland and even Scandinavia.

Growth creates new jobs

From 2011 to 2014, the social rooms for the employees were expanded and redesigned, a production hall was added and the office wing has been renewed. That created eleven more jobs. FMG has grown continuously over the years and has constantly adapted to the needs and requirements of the present and future. This also includes securing our company's succession with the appointment of Anja Wendt and Uwe Eilers, who have taken over the company's mangement after many years under directors Bernd Lehmann and Thomas Schuster ledership in a long-term handover.

By Sabine Hügelland | Newspaper: Ostseezeitung