Avoid downtime and remain able to work. With scrapers of FMG Förderelemente Mecklenburg GmbH.

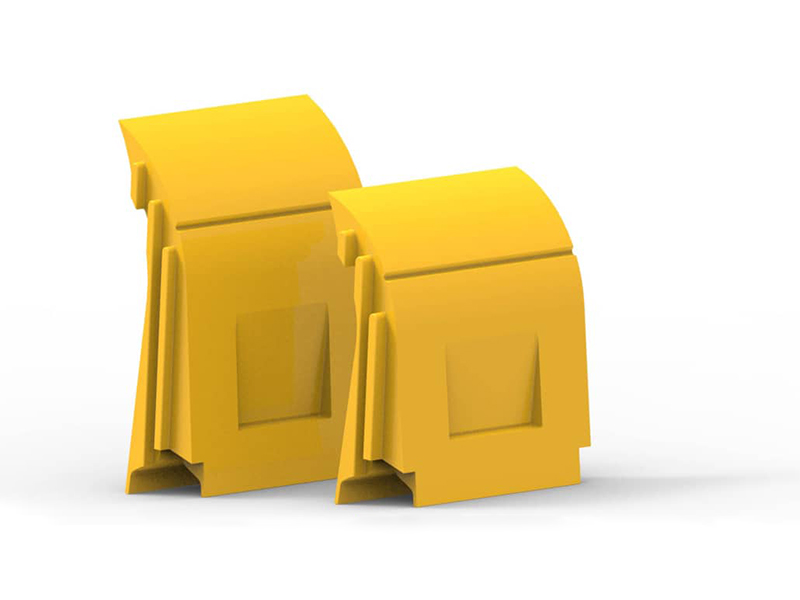

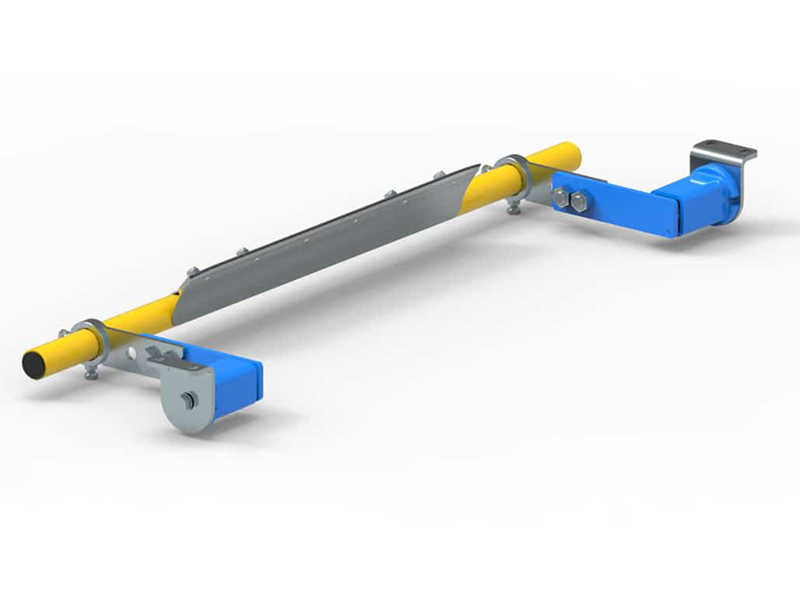

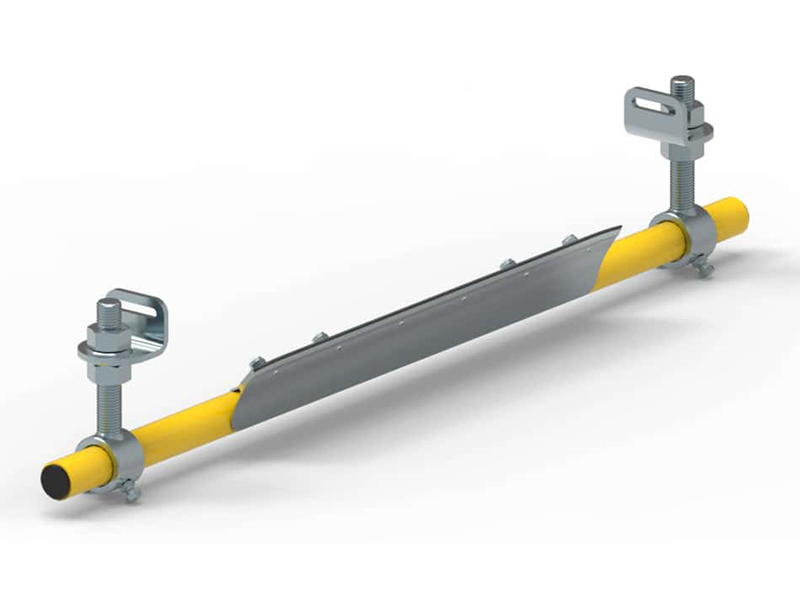

Scrapers are the most important element in belt cleaning. Hard-wearing scraper blades made of hard metal, rubber or brushes are elastically pressed against the conveyor belts. They adapt dynamically to the belt surface and wear. In this way, material residues are wiped off and the belt is reliably cleaned.

An unclean belt can cause excessive material buildup under the return idlers. A scraper prevents this and you avoid unnecessary additional costs for cleaning the system and the resulting downtimes.

We use PEMA UTR scrapers. Because these are characterized by particularly good quality and an appropriate price-performance ratio. In addition, they are easy to handle. If individual spare parts are required, they can be obtained from us. Furthermore, we offer the installation and maintenance of the wipers with our assembly team.

The product “Band stations” from the house FMG Förderelemente Mecklenburg GmbH forms an essential part in the field of Materials Handling. They are specially designed for the efficient construction of conveyor systems Upper belt stations (OBS) installed below the top strap, while the Subband stations (UBS) are responsible for returning the belt. These tape stations are standardized according to DIN 22170 and tailored to the dimensions of the tape rolls. The tape rolls are standardized in DIN 15207. A series of belt stations results in conveyor belts, such as those in gravel quarries that can run for kilometers.

The Conveyor rollers, which are used in these stations, can be made from Steel, Stainless Steel or Plastic .

The steel storage floors can be made from deep-drawn sheet steel or from round material. The plastic floors are created using the injection molding process. The support rollers can be sealed from the outside with various sealing systems. The specific design results from the tube-axle combination. The tape rolls serve, among other things, as: basic component of belt stations and conveyor belts.

High quality conveyor technology

At the core of the product description are the tape rolls, the arrangement of which is carried out strictly in accordance with DIN 22107. This product is designed to deform the strap to create a trough, which is a efficient conveying of materials enabled. The quality and nature of the Tape stations are reflected in the solid and proven construction. Depending on your needs, you can between different versions to get voted.

The Individuality of the tape stations is shown in the U-steel threshold, with a trough between 10° to 40° and a camber of 0° to 3°, suitable for belt widths from 400 mm to 2000 mm. In terms of area of application, the tape stations from FMG applicable in many ways. Industries such as gravel and chippings plants or agriculture benefit from the efficient conveying solutions.

FMG: We have the right solution

The specialty of the FMG tape stations lies in their high-quality and precise workmanship, which enables effective and long-lasting use. Potential buyers should know that there are standard versions for specific roll diameters and troughs for each belt width, which means the Selection and implementation of tape stations facilitated and thus supports seamless operation of the conveyor systems.

Our band stations are robust, reliable and durable. This means they meet the specific needs of our customers. They are also made from high-quality materials and are designed to... to withstand the demands of daily operations. We take the utmost care Quality of our products so that our customers can rely on one long-term, reliable and efficient use being able to leave.

Our specialists from the FMG team will be happy to advise youto exploit the full potential of our products.

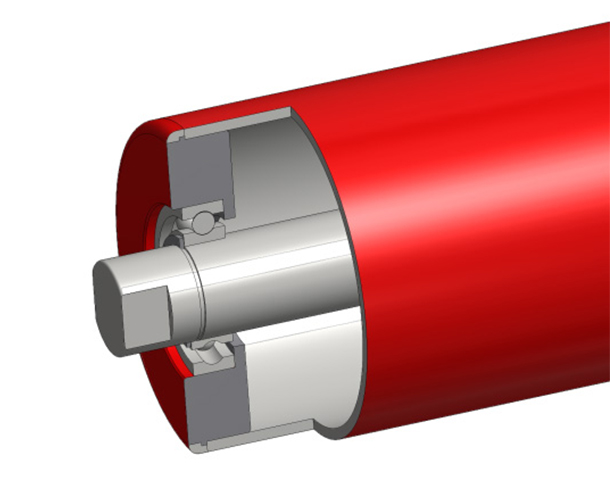

Are you looking for a high quality and durable product as a fundamental element for belt stations and conveyor belts that meets the requirements of your industry? With our tape rolls, you decide on the best-selling type of roll FMG FÖRDERELEMENTE MECKLENBURG GMBH. This product is suitable for transporting medium to heavy bulk goods in different areas.

FMG belt rollers for your conveyor technology: Highest quality and a long service life

FMG conveyor rollers are high-quality, versatile conveyor rollers with a long service life that we manufacture in-house. They are the heart of belt stations and conveyor belt systems.

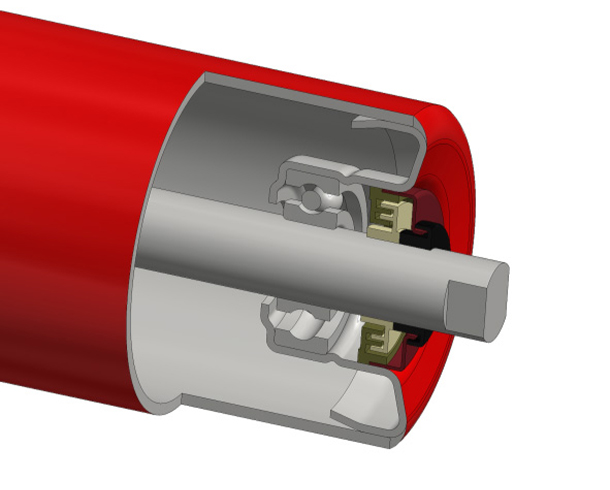

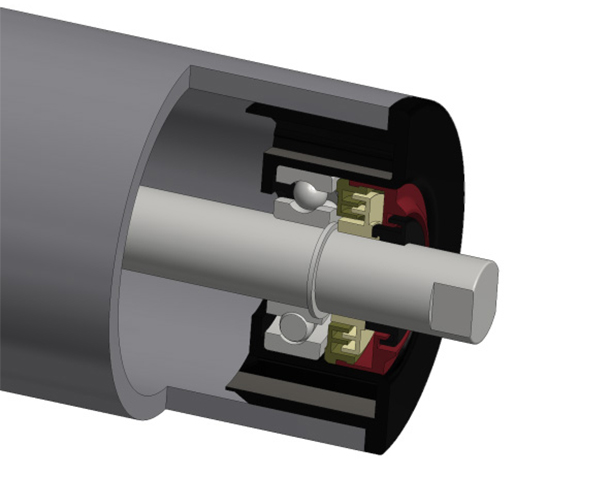

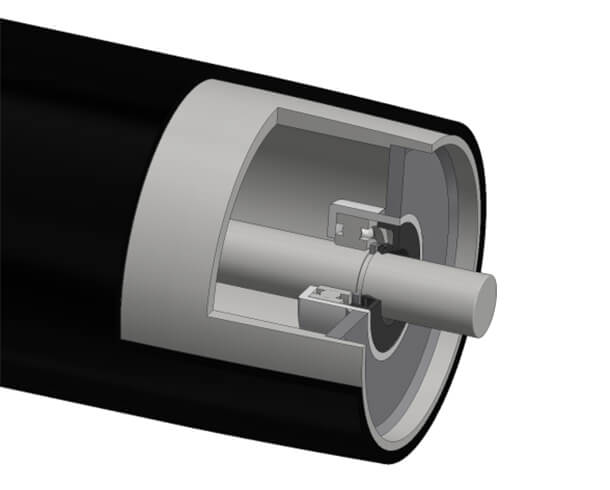

The bearing floors of these idlers are made of steel or plastic (polypropylene), which are welded and/or pressed into the roller body (idler tube). They are made of deep-drawn sheet steel or solid material. Depending on the type series, different designs are possible for the integration of the bearing bases in the roller body.

With regard to the composition of our rolls of tape, we naturally take different circumstances into account. For example, we offer types with different labyrinth seals to enable the belt rollers to perform even at high temperatures or in a very dusty environment.

Our standard version (type 420/421) is available in the attractive RAL 3000 (flame red) finish. Of course, painting in other RAL tones is also possible. Since we always have some rolls with standard dimensions in stock, you can usually expect short delivery times from us - in the event of an average, we can also deliver within a few days. We can also offer you tailor-made designs according to your individual needs in first-class quality.

FMG Förderelemente Mecklenburg looks forward to your inquiry

Do you have any questions about our tape rolls? Let's talk about your very special requirements in your conveyor system. We would be happy to advise you on our custom-made belt rolls and on possible special designs that fit your challenge exactly.

Drive and tail pulleys are an essential part of conveyors and play an important role in efficient and reliable conveyance of materials and goods. These drums are mainly installed at the beginning and end of a conveyor belt and essentially consist of three components: the side parts, the tube and the axle. Internally mounted tail pulleys (UTI) do not require additional bearings to function properly as these are integrated. In contrast, welded drums (AT and UT) or drums with clamping set (ATSP and UTSP) are installed and operated with pillow block bearings.

The FMG Förderelemente Mecklenburg GmbH from Körchow offers drive and idler pulleys standard in diameters from 150 to 320mm that have been specially developed for the needs of different conveying applications. We pride ourselves on being able to offer a wide range of drive and tail pulleys to provide our customers with tailored solutions that best meet their individual requirements.

Conveyor technology in first-class quality

Our FMG drive and tail pulleys are characterized by their Robustness and durability out of. We rely on high-quality materials and a stable construction in order to be able to withstand the demands of daily use.

You have the opportunity to state your specific requirements for the dimensions and material use of our drums in order to receive a tailor-made solution. This not only enables our drive and tail pulleys to be perfectly integrated into existing systems, but can also become one Increase in efficiency in the operational process .

Our drive and tail pulleys are used in a variety of applications, such as conveyor systems for loading in ports, in grain silos and in the construction industry. In all these areas of application, the robust construction and individual production is a big plus and thus ensures a reliable and trouble-free operation.

Our experts from the FMG team will be happy to advise you on how to exploit the full potential of our products.

FMG: We have the solution for you

With our drive and idler pulleys, we offer you the perfect solution if you are looking for high-quality spare parts for your conveyor system. With our drums, your conveyor belts can be driven or deflected efficiently, which leads to smooth operation of the systems.

The drive drums are included external motors operated and are designed to run through spherical overturning of the drum body ensure perfect belt centering during the run. This increases the efficiency of the system and reduces downtime.

Our drive and tail pulleys are not only robust, reliable and durable, but also available in different sizes and designsto meet the specific needs of our customers. In addition, they will high quality materials Manufactured and designed to withstand the rigors of everyday use. The greatest care is taken with the quality of our drums, so that our customers can rely on long-term, reliable and efficient operation.

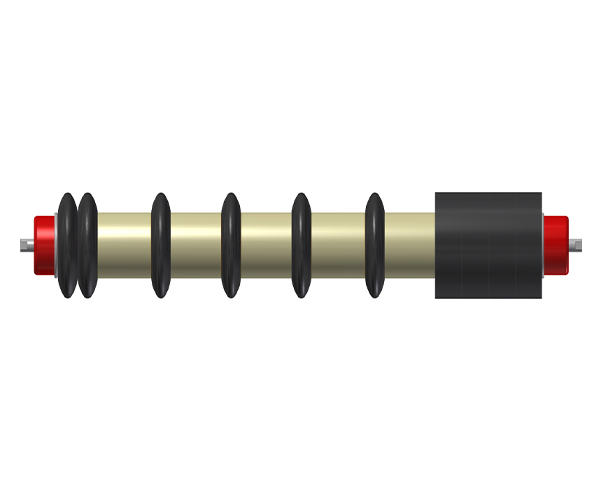

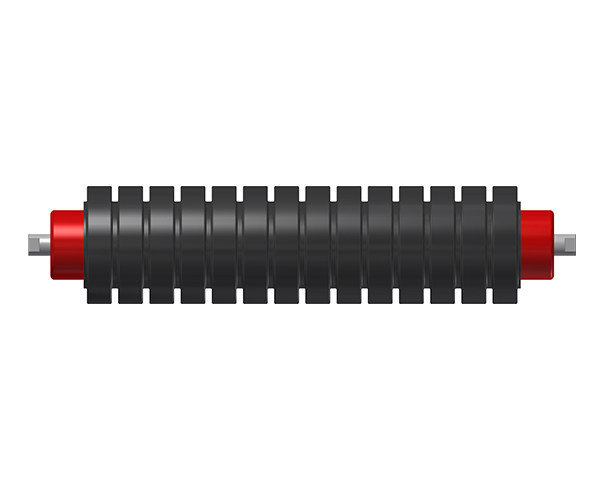

Regardless of whether it is coal, sand, cement or other bulk materials, loose granular materials are conveyed particularly efficiently with belt conveyor systems. The conveyor belt is guided by belt rollers for smooth operation. In the task area of the conveyor belt, buffer ring rollers are used to cushion the impacts caused by coarse conveyed material. In the return run of the belt, support ring rollers are used to support the belt and help conveyed material adhering to the conveyor belt to fall off more easily. With special seals, the rollers can also be used in dusty environments. Her FMG Förderelemente Mecklenburg GmbH from Körchow supplies high-quality conveyor rollers that perfect for transporting bulk goods are suitable. Buffer and support rings can be attached as accessories to any product in the FMG castor portfolio in order to To support belt and thus absorb the falling energy of the conveyed goods. Depending on the individual application, different support ring shapes and arrangements are advantageous. We would be happy to inform you about the desired solutions for your conveyor system.

Buffer and support ring rollers with the best quality features

Our buffer and support ring rollers, which can be individually configured according to your wishes and required bandwidths, help to increase the service life of the conveyor system and protect the conveyor belt from damage. The buffer and support rings, made of rubber or a higher-quality but wear-resistant polyurethane, cushion the fall energy of the material being conveyed, ensure that adhering materials trickle off and thus offer proven protection for your conveyor system. We focus on providing you with tailor-made solutions so that you can get the best possible benefit from our FMG buffer and support ring rollers for your conveyor system.

Our solution for your plant in the bulk material sector

Our buffer and support ring rollers are required in particular when bulk materials have to be transported on conveyor belts in a dirty and dusty environment. Thanks to our many years of experience, one excellent selection of materials as well as the quality features of our products, we always have a suitable solution for your requirements. The specific choice of material for the buffer and support rings guarantees, in addition to cushioning the material to be conveyed, a clean belt and improves belt return. With the help of attachments for the rings, they can be secured against lateral displacement. This allows for stabilization from the outside clamping and welding rings and for securing between the backup rings spacers be used.