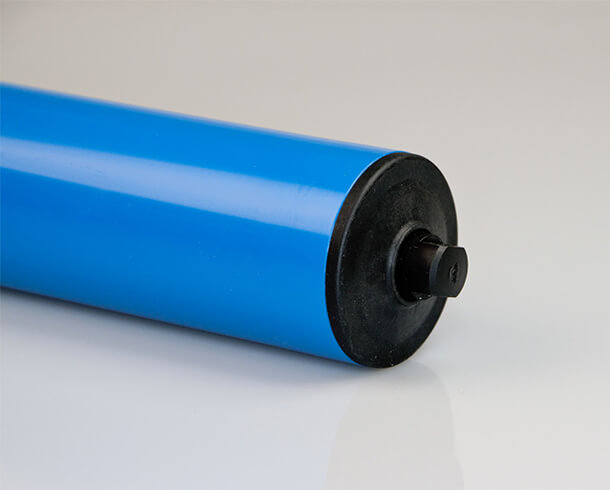

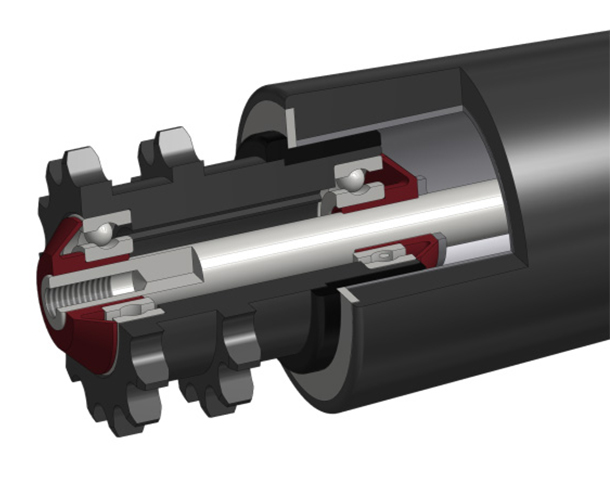

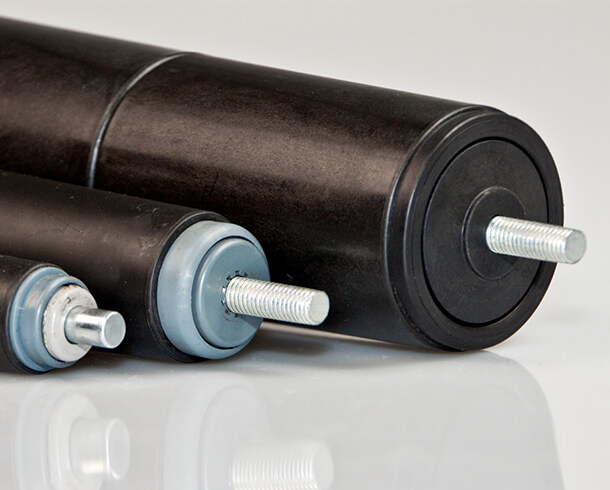

Conveyor rollers with storage shelves made of plastic enjoy because of their versatile application possibilities a growing popularity. Compared to conventional idlers with steel bearing floors, they offer numerous advantages that ensure smooth material transport in conveyor systems. The plastic bearing bases are firmly pressed into the reel body and enable integration in different designs. So they are suitable for light to medium loads and are used in various industries.

Robust construction

Carrying rollers with plastic bearing bases are a robust and reliable component in many industrial conveyors. The plastic bearing base is pressed into the roller body and enables the transport of light to medium-heavy goods. Thanks to their durable construction, they are durable and can also be used in particularly demanding environments. Whether in the food and pharmaceutical industry, at airports or in agriculture - conveyor rollers with plastic bearing bases are a solution for many applications.

Variety of materials and a long service life: advantages of plastic idlers

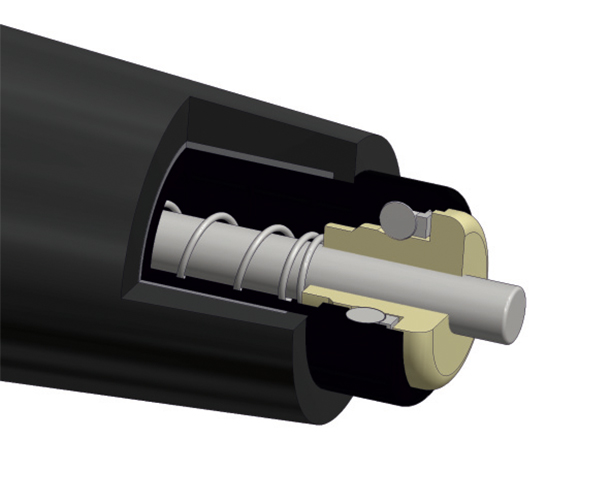

One of the most important properties of conveyor rollers with plastic bearing bases is the possibility of designing them with a very small diameter, for example with a diameter of 16x1mm. This means that they can also be used in narrow conveyor systems with a lack of space. In addition, these idlers are compared to others very quiet, which is important in many areas. The use of Plastic as a material also offers a very good seal against dust and dripping water, which the Extends the service life of the rollers and reduces maintenance.

The rollers with plastic bearing bases are suitable for light to medium loads. They can be integrated in different versions, depending on the requirements of the respective conveyor system.

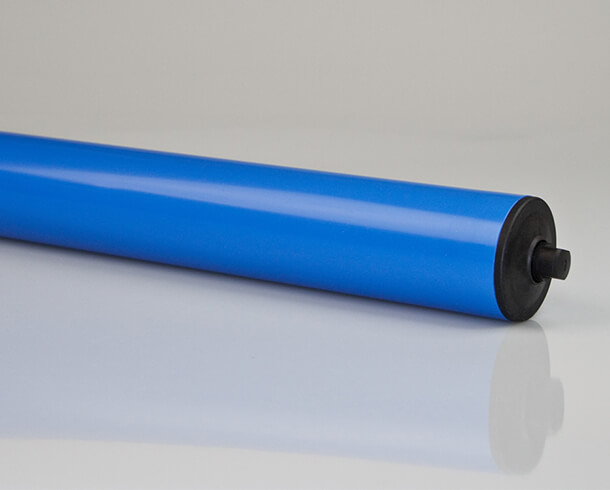

Another advantage of idlers with plastic bearing bases is that they also made conductive on request can become. This special design is particularly important in environments where electrostatic charges must be avoided. This is essential primarily in electronics manufacturing or in the area of chemical production.

Long service life thanks to good sealing: properties of conveyor rollers with plastic bearing bases

Carrying rollers with plastic bearing floors provide a good seal. This increases the life of the rollers. The plastic bearing base is pressed into the reel body and offers compared to other materials such as Steel or aluminum provide a very good seal against dust and dripping water. This increases the protection against moisture or dirt particles in the rollers, which reduced friction and extends the life of the rollers. In addition, the seal reduces maintenance as the rollers do not need to be cleaned or replaced as often.

Flexibility through individual designs: carrying rollers with plastic bearing floors

Conveyor rollers with plastic bearing bases can be designed as gravity conveyor rollers or as driven rollers. The driven variants are equipped with a bead, gear wheel or toothed belt drive and thus enable a precise control of the conveying speed. Overall, idlers with plastic bearing bases offer an excellent choice for customers looking for an efficient and reliable solution to their conveying needs.

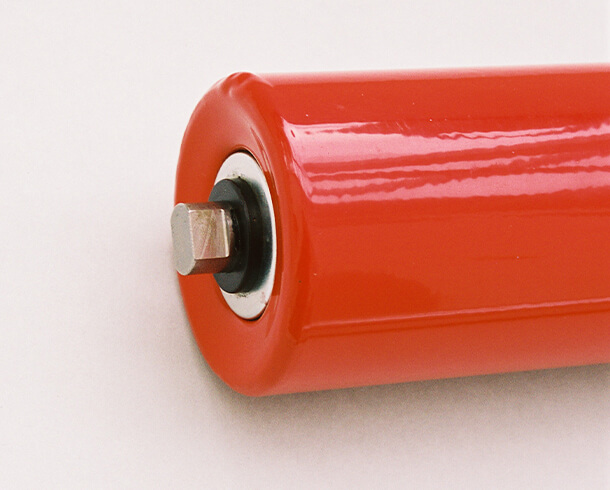

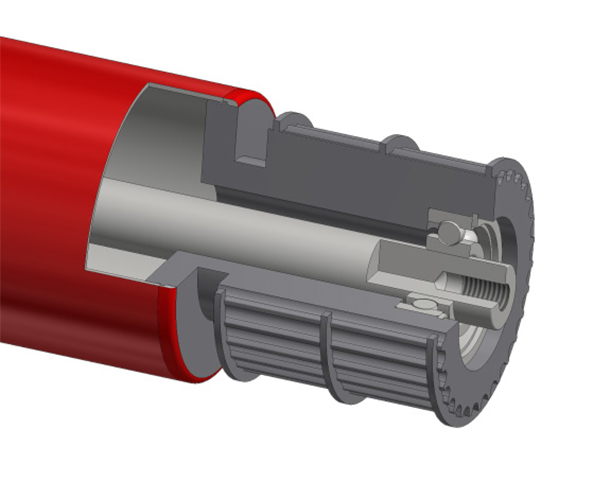

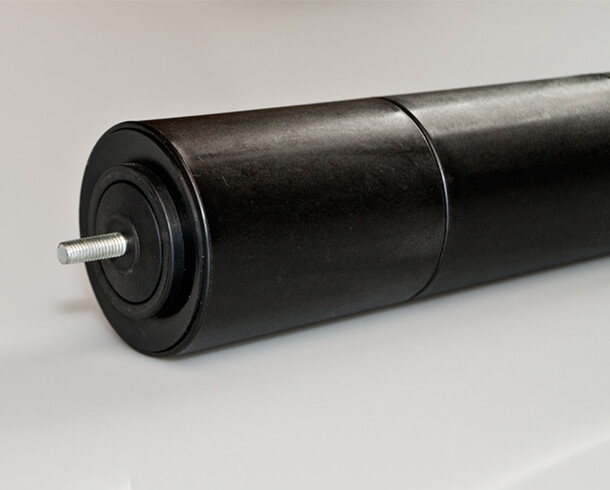

When it comes to the efficient and reliable conveying of materials and goods, we are Conveyor rollers a indispensable element in many industrial applications. Carrying rollers with sheet steel bearing floors from yours FMG Förderelemente Mecklenburg GmbH from Körchow offer an excellent solution for the transport of medium-heavy and heavy loads and materials on conveyor belts and roller conveyors. With your robust, electrically dissipative sheet steel storage floor These idlers are made of deep-drawn sheet steel, which is pressed into the tube particularly durable and resistant against wear and tear. They are of different sizes with a Tube diameter from 30mm to 108mm available and can be customized to the specific requirements of your application. If you are looking for reliable and durable conveyor rollers, you will make the ideal choice with our tailor-made conveyor rollers with sheet steel bearing floors.

First-class technology for your conveyor system

If you heavy loads and materials have to transport, our idlers with sheet steel bearing floors are an excellent choice for your conveyor system. Compared to Carrying rollers with plastic bearing floors offer greater load capacity and durability. The sheet steel bearing floors are robust and resistant to wear and tear, which is reflected in a longer service life of the idlers. In addition, the idlers can be equipped with different types of bearings to optimal performance and durability to ensure. Some of the common bearing types are Deep groove ball bearings or conical ball bearing.

Our focus is on customized solutions, to give you a comprehensive and promising potential benefit of the idlers with sheet steel bearing floors. Let the FMG team of experts advise you to fully benefit from our products.

Optimal solution for your system in the general cargo area

With our rollers with sheet steel bearing floors, we offer you reliable technology for your individual needs in the general cargo area. The selected type of idler allows the transport of light to heavy goods effortlessly and is also maintenance and reduce your recruitment costs.

Do you have a small conveyor system or only need a few idlers with sheet steel bearing floors? No problem! We also manufacture in small editions.

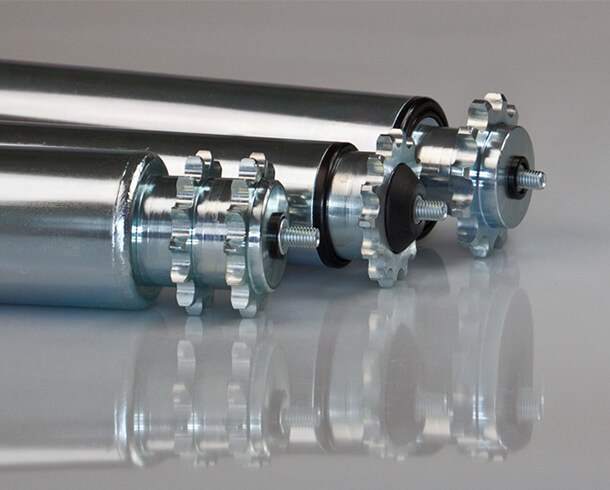

Whether parcels, pallets, boxes or other piece goods: The transport is particularly efficient with powered Conveyor rollers. But do not choose just any product, but one of high quality. That allows one smooth workflow and durability. You can get first-class driven conveyor rollers with different drive types from us – yours FMG Förderelemente Mecklenburg GmbH from Korchow. They are suitable for continuous conveyance as well as for accumulating drives. For proper operation we use Drive elements made of plastic or steel. The counter bearing corresponds to the type of non-driven support roller. Regardless of your area of activity, we would be happy to provide you with detailed information tailor-made solutions for your system.

Smart conveyor technology in premium quality

You can rely on our driven idlers. she support your work processes efficiently and convince with a low risk of failure. Their long service life thanks to premium quality helps to achieve sustainable cost savings that have a positive impact on sales. We focus on individual solutions so that you benefit holistically and effectively from the FMG-driven conveyor rollers. All dimensions are, of course, customer-specific, because an impeccable consulting service is an integral part of our company philosophy. Our Flexibility We also make this clear with our idlers with special drives, which we also manufacture in small quantities as required.

FMG: We have the solution for you

With our driven conveyor rollers, we offer you reliable technology. Since we can use a wide variety of drive types for you according to your needs, there is the optimal driven idler roller for every operating system. With the adeptly selected role type, this succeeds Reliable transport of light to heavy goods. If an accumulation drive is used, the conveyed goods can be stopped. This intermediate step is essential for some operational processes.

If you're looking for an efficient way to move packages, fabrication and assembly parts, boxes, or other unit loads on tortuous conveyors, consider conical idlers to use. At her FMG Förderelemente Mecklenburg GmbH from Körchow you get high quality Conveyor rollers, which are ideal for building curves in conveyor systems. Our drive elements made of plastic and steel ensure smooth operation. No matter in which area you are active - we would be happy to inform you about tailor-made solutions for your system.

Top class conical rollers

Our tapered idlers high quality materials are reliable, durable and effectively support your work processes by sustainably saving costs. We focus on individual solutions, so you can benefit from our conical idlers holistically and promisingly.

As standard, conical elements are pressed onto a steel roller during production, resulting in a cone shape with a linearly increasing outer diameter. Furthermore, conical steel tubes or rubber coatings can be used.

We have the solution for your winding conveyor belts

Our tapered idlers offer you one reliable technology for the construction of curve elements in conveyor systems with the standard ones Curve radii R=300mm, R=500mm and R=800mm. The selected type of castor enables the transport of light to heavy goods reliably.

Do you only need a few conical conveyor rollers? No problem! We offer you too Small quantities at a fair price

Rollers and rails are indispensable components in the world of Materials Handling. These versatile components consist of Steel or plastic rollers, which are integrated into a basic profile. Your main task is that reliable transport of general cargo in a linear movement. At FMG Förderelemente Mecklenburg GmbH you have come to the right place, regardless of whether you need individual rollers or complete roller rails. Delivery of individual rolls is just as possible as delivery of entire roller rails.

Conveyor technology for every area of application

Our focus here is on Rollers and rails, which are suitable for every area of application thanks to their versatile designs. Rollers and rails are designed to fit almost every requirement profile. They are available in various designs to meet different needs in numerous industries. This versatility is a trademark of the products from FMG Förderelemente.

The Rollers and rails from FMG are characterized by their robust and compact design. This not only ensures that Longevity of the products, but also theirs capacity in demanding environments. The durable materials and careful workmanship ensure that these conveyor elements provide reliable performance even under strain. We know our customers’ challenges and know how to solve them.

For customers involved in pallet transport Rollers and rails an indispensable aid. They enable the smooth transport of pallets and the robust construction ensures that heavy loads can be moved without any problems. Transporting sensitive and fragile goods requires precision and caution. FMG's rollers and rails make this possible gentle and safe transport, without damaging the goods. The versatility of the rollers and rails is ultimately reflected in the range of goods transported. Whether it's light products or medium-heavy materials - these conveyor elements handle the task confidently.

FMG: The solution for the general cargo sector

Rollers and rails are essential building blocks in the world of conveyor technology. At FMG Förderelemente Mecklenburg GmbH You will find a wide range of products that are characterized by their versatility, robustness and adaptability. Whether you need pallet transport, the transport of fragile goods or the movement of light to medium-heavy goods, these conveyor elements offer reliable solutions. With various materials and load capacity options, they are able to meet the needs of different industries and applications. Choose FMG products to optimize your conveyor systems and ensure smooth material transport.

Our specialists from the FMG team will be happy to advise youto exploit the full potential of our products for your needs.