Rollers and rails are indispensable components in the world of Materials Handling. These versatile components consist of Steel or plastic rollers, which are integrated into a basic profile. Your main task is that reliable transport of general cargo in a linear movement. At FMG Förderelemente Mecklenburg GmbH you have come to the right place, regardless of whether you need individual rollers or complete roller rails. Delivery of individual rolls is just as possible as delivery of entire roller rails.

Conveyor technology for every area of application

Our focus here is on Rollers and rails, which are suitable for every area of application thanks to their versatile designs. Rollers and rails are designed to fit almost every requirement profile. They are available in various designs to meet different needs in numerous industries. This versatility is a trademark of the products from FMG Förderelemente.

The Rollers and rails from FMG are characterized by their robust and compact design. This not only ensures that Longevity of the products, but also theirs capacity in demanding environments. The durable materials and careful workmanship ensure that these conveyor elements provide reliable performance even under strain. We know our customers’ challenges and know how to solve them.

For customers involved in pallet transport Rollers and rails an indispensable aid. They enable the smooth transport of pallets and the robust construction ensures that heavy loads can be moved without any problems. Transporting sensitive and fragile goods requires precision and caution. FMG's rollers and rails make this possible gentle and safe transport, without damaging the goods. The versatility of the rollers and rails is ultimately reflected in the range of goods transported. Whether it's light products or medium-heavy materials - these conveyor elements handle the task confidently.

FMG: The solution for the general cargo sector

Rollers and rails are essential building blocks in the world of conveyor technology. At FMG Förderelemente Mecklenburg GmbH You will find a wide range of products that are characterized by their versatility, robustness and adaptability. Whether you need pallet transport, the transport of fragile goods or the movement of light to medium-heavy goods, these conveyor elements offer reliable solutions. With various materials and load capacity options, they are able to meet the needs of different industries and applications. Choose FMG products to optimize your conveyor systems and ensure smooth material transport.

Our specialists from the FMG team will be happy to advise youto exploit the full potential of our products for your needs.

What information does FMG need to create an offer for rollers/roller rails?

Required when preparing an offer for roller and roller rails FMG Förderelemente Mecklenburg GmbH specific information to create a tailored offer. These include:

- Load capacity in kg (per roll/roll): Load capacity is crucial to ensure that the roller rails meet the specific requirements of their application. It indicates how much weight each roll or roll can carry.

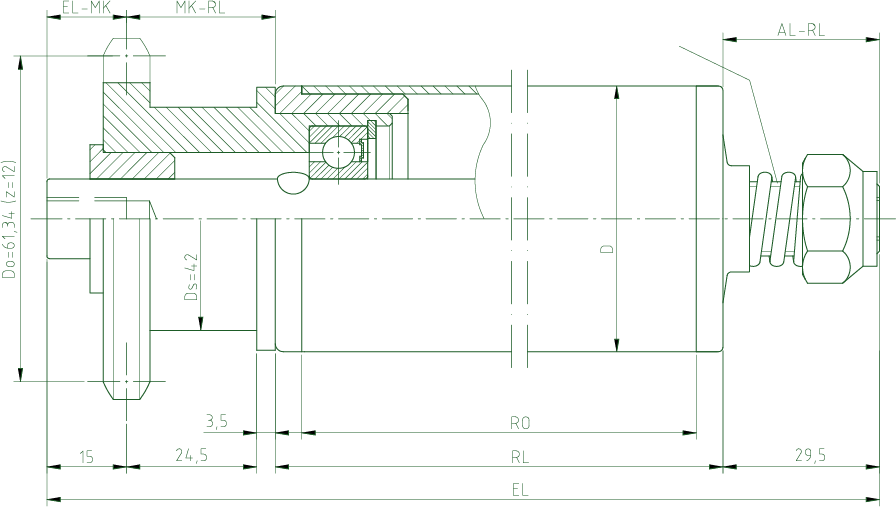

- Diameter: The diameter of the rolls or rolls influences the size and handling of the goods to be transported. A suitable diameter ensures efficient movement of goods.

- Material: The material of the rollers and rollers determines their durability and suitability for different environments and loads. Different materials offer different properties in terms of abrasion resistance and resilience.

- Length: The length of the roller rails must be tailored to the dimensions of the goods to be transported and the spatial conditions.

- Storage: The type of storage influences the smooth running and lifespan of the rolls. Different storage options are suitable for different applications and loads.

You can find a detailed overview of the different versions in our catalog in the roller rails chapter.

With this information we can create a quote tailored to your exact needs and ensure you receive rollers and rails suitable for your conveyor applications. Our team of experts is available to assist you with selection and configuration.