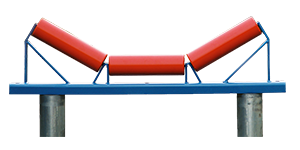

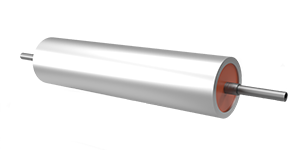

Bulk material rollers

Conveyor rollers from this category are suitable for transport of granular or powdery material, which run over the conveyor system or should also be poured, for example gravel, cement, pellets, etc.

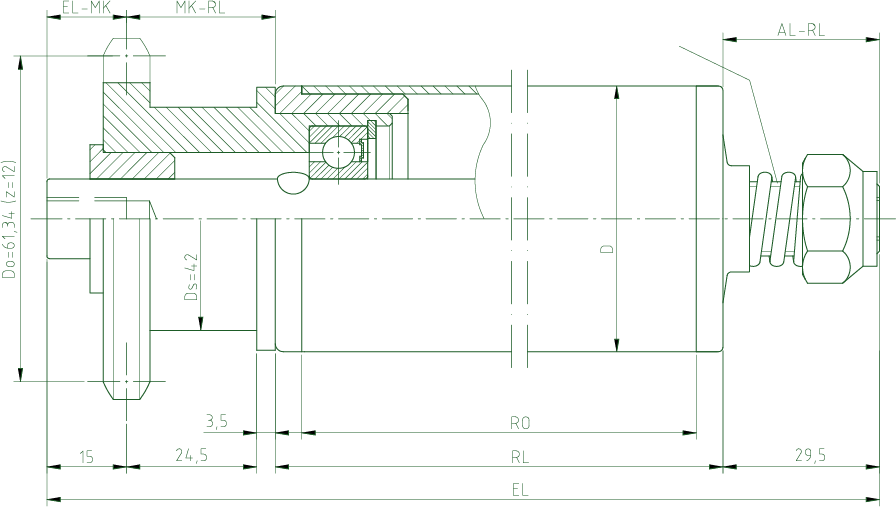

We manufacture rolls of the highest quality that fit your requirements exactly.

We are also the right contact for small quantities in order to be able to respond even better to the needs of your conveyor system.

arrange a callback

Arrange a non-binding consultation with our specialist advisors to determine your exact requirements.

We look forward to you.