The product “Band stations” from the house FMG Förderelemente Mecklenburg GmbH forms an essential part in the field of Materials Handling. They are specially designed for the efficient construction of conveyor systems Upper belt stations (OBS) installed below the top strap, while the Subband stations (UBS) are responsible for returning the belt. These tape stations are standardized according to DIN 22170 and tailored to the dimensions of the tape rolls. The tape rolls are standardized in DIN 15207. A series of belt stations results in conveyor belts, such as those in gravel quarries that can run for kilometers.

The Conveyor rollers, which are used in these stations, can be made from Steel, Stainless Steel or Plastic .

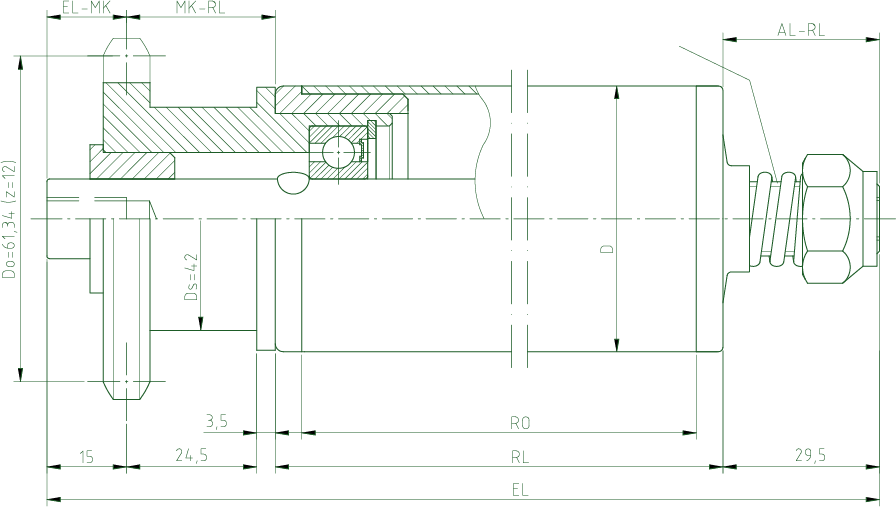

The steel storage floors can be made from deep-drawn sheet steel or from round material. The plastic floors are created using the injection molding process. The support rollers can be sealed from the outside with various sealing systems. The specific design results from the tube-axle combination. The tape rolls serve, among other things, as: basic component of belt stations and conveyor belts.

High quality conveyor technology

At the core of the product description are the tape rolls, the arrangement of which is carried out strictly in accordance with DIN 22107. This product is designed to deform the strap to create a trough, which is a efficient conveying of materials enabled. The quality and nature of the Tape stations are reflected in the solid and proven construction. Depending on your needs, you can between different versions to get voted.

The Individuality of the tape stations is shown in the U-steel threshold, with a trough between 10° to 40° and a camber of 0° to 3°, suitable for belt widths from 400 mm to 2000 mm. In terms of area of application, the tape stations from FMG applicable in many ways. Industries such as gravel and chippings plants or agriculture benefit from the efficient conveying solutions.

FMG: We have the right solution

The specialty of the FMG tape stations lies in their high-quality and precise workmanship, which enables effective and long-lasting use. Potential buyers should know that there are standard versions for specific roll diameters and troughs for each belt width, which means the Selection and implementation of tape stations facilitated and thus supports seamless operation of the conveyor systems.

Our band stations are robust, reliable and durable. This means they meet the specific needs of our customers. They are also made from high-quality materials and are designed to... to withstand the demands of daily operations. We take the utmost care Quality of our products so that our customers can rely on one long-term, reliable and efficient use being able to leave.

Our specialists from the FMG team will be happy to advise youto exploit the full potential of our products.

For which belt widths are there standard upper belt stations?

In upper conveyor stations used in various industrial applications, the Correct belt widths are crucial. As standard, we offer top belt stations for a wide range of belt widths to meet individual requirements.

Our upper conveyor stations are able to Support belt widths from 400 mm to 2.000 mm. The right support rollers are of great importance here, as they contribute significantly to stability and performance. The support rollers vary in roller length depending on the design and can Values from 160 mm to 1.100 mm exhibit. You can find more detailed information about the specific idler roller lengths in our catalog or in a personal consultation. Our experts are available to help you select the optimal top conveyor station for your needs.

The variety of belt widths available in our upper belt stations, combined with the appropriate support rollers, makes it possible to to implement tailor-made solutions for various conveying applications and thus ensure smooth material movement and process optimization.

What information about the tape stations do we need to make you an offer?

To give you one tailor-made offer to create for our tape stations, we need some important information, which help us to optimally meet your requirements. Here is the information that will be useful to us when preparing an offer:

- Quantity: Please let us know how many tape stations you need. The number of pieces influences the total costs and production planning.

- Number of divisions (2-part or 3-part): Clarify whether you need 2-piece or 3-piece belt stations as this will affect design and assembly.

- Belt width: Specify the desired belt width, as this significantly influences the capacity of the belt station.

- Roll diameter: Roller diameter information is important to correctly dimension load capacity and material flow.

- roll length: Let us know the desired roll length, which may vary depending on the application. The roll length can be found in our catalog depending on the belt width.

- Trough (standard 30°): By default the trough is 30 degrees, but we can adjust this to suit your specific requirements if necessary.

- Profile threshold: Specify which profile you want for the threshold, as different profiles support different conveyor applications.

- Fall: Information about the fall helps us to produce the belt station correctly.

- Mounting: Clarify how you want to attach the tape station, for example by screwing or clamping.

- Belt station material/surface: Tell us what material the belt station should be made of and whether you have any special requirements for the surface finish.

With this information we can create a quote tailored to your exact needs and ensure you receive the optimal belt station for your conveyor applications. Our team of experts is available to assist you with selection and configuration.